Reducción del Impacto Ambiental Mediante la Pirólisis

Desviando Millones de Toneladas de Vertederos Anualmente

La pirólisis es la tecnología perfecta para evitar que estos residuos llenen los vertederos del mundo, ya que podemos convertir casi cualquier residuo que pueda ser quemado y que requiera eliminación, en petróleo (combustible). Con más de 250 millones de toneladas producidas cada año, el procesamiento de residuos para generar energía se está convirtiendo en una fuente indiscutible de energía limpia. Esta innovadora solución de tratamiento está diseñada para descomponer materiales que no son biodegradables, por ejemplo, neumáticos usados, bien conocidos por ocupar espacio en los vertederos y permanecer allí indefinidamente. Los neumáticos usados se transforman en productos utilizables mediante pirólisis y, así de simple, contamos con una alternativa efectiva para evitar su eliminación en vertederos. Estudios han mostrado que millones de neumáticos usados podrían ser tratados anualmente a través de la pirólisis de neumáticos, contribuyendo significativamente a la desintoxicación del medio ambiente. Esto nos está ayudando no solo a reducir los residuos, sino también a disminuir la dependencia de los vertederos y, por ende, a promover una gestión sostenible de los residuos.

Prevención de emisiones tóxicas y incendios subterráneos

La pirólisis como solución para residuos no solo puede eliminar las emisiones dañinas que provienen de la destrucción de cargas de neumáticos usados en el aire. La combustión convencional de neumáticos libera gases altamente tóxicos al aire, mientras que la pirólisis no lo hace, ya que es un proceso que ocurre en ausencia de oxígeno. Los informes destacan que la pirólisis también reduce la susceptibilidad a incendios subterráneos asociados a pilas de neumáticos, difíciles de controlar y peligrosos. Las comunidades pueden disfrutar de una mejor calidad del aire, menores riesgos para la salud y un entorno residencial más seguro cuando se utilizan sistemas de pirólisis. Por tanto, la pirólisis aporta no solo beneficios ambientales sino también para la salud pública, subrayando el papel que desempeña en proyectos de desarrollo sostenible.

Beneficios económicos de las operaciones de pirólisis de neumáticos

Ahorro de costos mediante procesamiento a baja temperatura

El primero es el aspecto financiero, ya que la pirólisis de neumáticos es rentable debido a su bajo requerimiento de temperatura. Comúnmente, el tratamiento de residuos y su posterior proceso de disposición se lleva a cabo mediante incineración u otras tecnologías de alta temperatura, lo cual no solo consume mucha energía, sino que también resulta costoso de operar. En la pirólisis a baja temperatura, inferior a 700 grados Celsius, los costos energéticos son mínimos, lo que permitiría reducir los costos de Shi MEOR en aproximadamente un 30%. La disminución significativa en la demanda de energía hace que el proceso sea sostenible y también factible desde un punto de vista económico. Por ejemplo, al utilizar sistemas de procesamiento que operan con un consumo energético mínimo, las empresas pueden ser más competitivas en el mercado, produciendo mejores resultados con una estructura de costos inferior a la del mercado, mejorando así su rentabilidad.

Fuentes de Ingresos por Petróleo, Negro de Humo y Acero

La industria de pirólisis de neumáticos usados tiene un inmenso potencial para generar múltiples fuentes de ingresos a partir de desechos, incluyendo aceite, negro de carbón y acero. Estos productos pueden venderse y utilizarse en diferentes industrias químicas y manufactureras. Las proyecciones de ingresos a nivel mundial para la industria de pirólisis de neumáticos podrían aumentar hasta alcanzar los 35 mil millones de dólares en 2025, una cantidad nada despreciable para cualquier país que busque impulsar su economía. Las empresas pueden incrementar sus márgenes de beneficio y volverse más sostenibles al ofrecer productos variados. El aceite producido mediante pirólisis puede transformarse en productos petroleros de mayor valor, y el carbono es un ingrediente clave en cauchos y adhesivos. El acero, aunque secundario, también genera rentabilidad. Estos distintos canales de ingreso no solo añaden valor al negocio y aseguran un futuro más saludable, sino que también hacen que el negocio de la pirólisis de neumáticos sea más sostenible.

Desglose del Proceso de Pirólisis

Descomposición Térmica Sin Oxígeno

La pirólisis es un proceso mediante el cual los compuestos orgánicos se descomponen químicamente a alta temperatura en ausencia de agente oxidante (oxígeno) para la combustión. Esta fragmentación, por tanto, permite la obtención controlada de subproductos de alta calidad, lo que la convierte en un proceso seguro y eficiente. La pirólisis es especialmente eficaz para reciclar caucho y otros polímeros, y siempre ha sido considerada un aspecto importante en la gestión de residuos. Dado que no implica combustión, la pirólisis evita los posibles riesgos de incendios y contaminación del aire, siendo un proceso confiable para las industrias de recuperación de materiales.

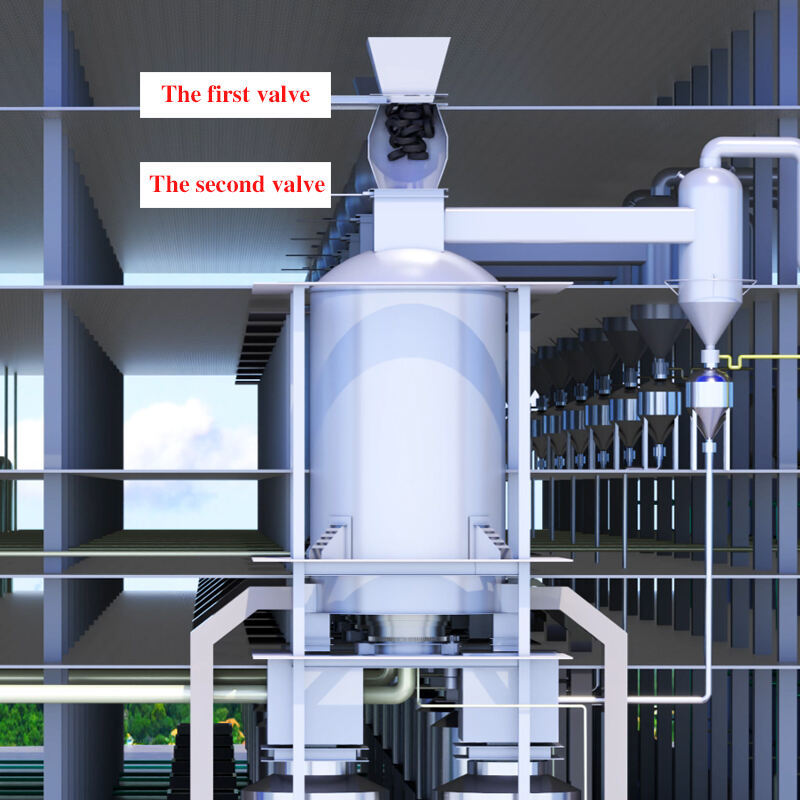

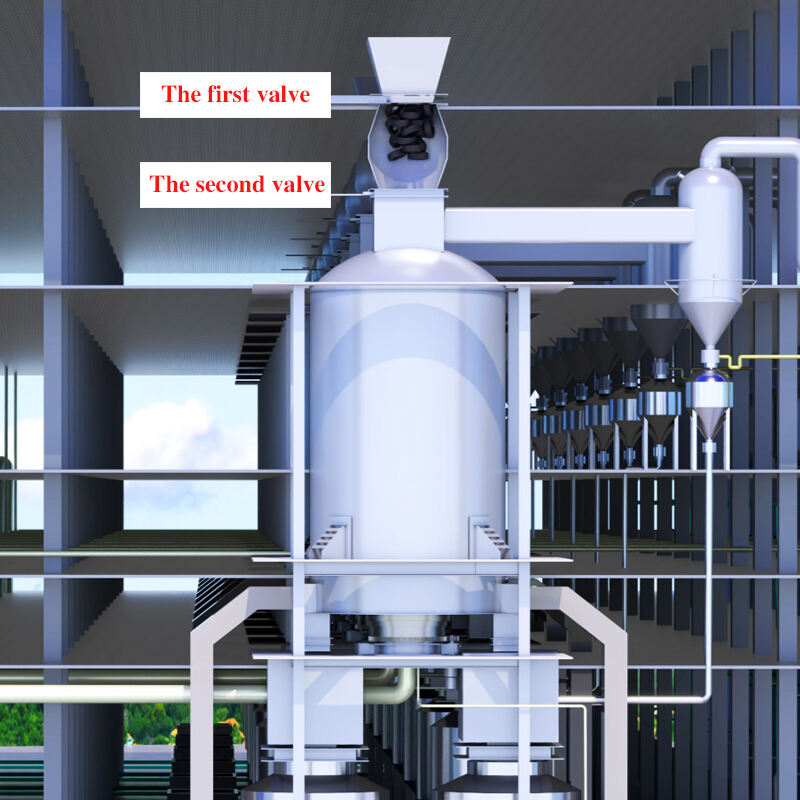

Sistemas de Alimentación Continua Eficientes en Energía

Combinación directa de sistemas de alimentación continua con el proceso de pirólisis para lograr una eficiencia máxima y menos tiempo improductivo. Estas máquinas permiten un procesamiento continuo y aumentan la productividad general, al tiempo que maximizan la recuperación de materiales. Al utilizar tecnologías avanzadas de alimentación, estos sistemas pueden incrementar la uniformidad en la calidad de los productos de salida y, por ende, producir subproductos más consistentes y de mayor calidad. El uso de sistemas de alimentación continua en plantas de pirólisis representa un enfoque estratégico hacia un reciclaje más sostenible y económico, que se ajusta perfectamente a la tendencia industrial hacia la eficiencia y la amigabilidad ambiental.

Para obtener más información sobre las plantas de pirólisis, explore las soluciones innovadoras ofrecidas por [Enviro y Antin Infrastructure Partners](#).

Impulsando la Innovación de la Economía Circular

Sistemas de Bucle Cerrado para Materiales Derivados de Neumáticos

Los sistemas cerrados de cuna a cuna son importantes para el desarrollo sostenible mediante el reciclaje regular y la reutilización de materiales derivados de neumáticos. Al introducir estos sistemas, podemos lograr tasas considerablemente más altas de recuperación de recursos, sustituyendo eficazmente el desperdicio de materiales. Esta nueva forma de pensar está muy alineada con el enfoque de la economía circular en encontrar maneras de reducir la carga ambiental. Por ejemplo, se ha encontrado que la industria del reciclaje de neumáticos puede lograr hasta un 50 % de reducción en el impacto ambiental mediante la aplicación de los principios de la economía circular. Al priorizar estos procesos de cuna a cuna, las empresas no solo fortalecen su compromiso con lo ecológico, sino que también tienen un impacto real en el medio ambiente en la búsqueda de metas de sostenibilidad mundial.

Alianzas Empresariales en Manufactura Sostenible

La alianza corporativa desempeña un papel fundamental en la promoción de la innovación para la fabricación sostenible y los métodos avanzados de pirólisis de neumáticos. Las asociaciones industriales permiten el intercambio de conocimientos y recursos, lo que conduce a ganancias significativas en eficiencia operativa. Al adoptar enfoques conjuntos, las empresas colaboran en el desarrollo de métodos de fabricación más sofisticados y ecológicos. Estas alianzas no solo resultan en avances tecnológicos que sustentan las actividades de MISIÓN CERO y sostenibilidad de las empresas involucradas, sino que también establecen una ventaja competitiva y fidelidad de marca. El patrocinio corporativo basado en el compromiso con prácticas sostenibles recibe recompensa en forma de atención mediática anticipada y generación de expectativa por parte de consumidores y grupos de interés sensibilizados con el medio ambiente.

Avances Tecnológicos en Pirólisis

Soluciones Automatizadas de Clasificación y Preprocesamiento

Las tecnologías de clasificación automatizadas han provocado un gran aumento en la eficiencia del procesamiento de neumáticos usados. Estos sistemas simplifican el proceso de separación de los materiales de los neumáticos, de forma que solo las materias primas más eficaces se envían a la pirólisis. Mediante la aplicación de opciones eficientes de preprocesamiento, se puede mejorar la calidad de los productos finales, como los materiales derivados de neumáticos y el aceite de pirólisis. Por otro lado, la inversión en automatización no solo incrementa la productividad, sino que también posibilita un mejor uso de los recursos, lo que puede contribuir directamente a la viabilidad y sostenibilidad del reciclaje de neumáticos.

Sistemas de Control de Emisiones para Operaciones más Limpias

Las plantas de pirólisis más modernas son hoy en día muy avanzadas en cuanto a su control de contaminación atmosférica, para hacer frente eficientemente a las preocupaciones sobre la contaminación. Estos dispositivos son especialmente importantes para suprimir la emisión de compuestos tóxicos en los procesos de pirólisis, cumpliendo con las estrictas normativas ambientales. Una investigación sobre la tecnología de control de contaminación confirma que es realmente factible minimizar las emisiones totales hasta en un 70 %, haciendo que las operaciones sean inofensivas y más limpias. Estas mejoras ayudan a garantizar el cumplimiento ambiental y la sostenibilidad operativa de la instalación, un elemento clave para el futuro de la industria del reciclaje de neumáticos, escribe Elisabeth Stahura.

Sección de Preguntas Frecuentes

¿Qué es la pirólisis y cómo reduce los residuos en vertederos?

La pirólisis es un proceso de descomposición térmica en un entorno libre de oxígeno, que convierte materiales como los neumáticos usados en productos valiosos. Al reducir la dependencia de los vertederos, la pirólisis evita la acumulación de residuos no biodegradables.

¿Cómo evita la pirólisis las emisiones tóxicas?

La pirólisis elimina emisiones tóxicas al procesar materiales en un entorno libre de oxígeno, a diferencia de los métodos tradicionales de combustión que liberan contaminantes perjudiciales.

¿Cuáles son los beneficios económicos de la piroólisis de neumáticos?

La pirólisis de neumáticos ofrece ahorros de costos mediante un procesamiento energéticamente eficiente a baja temperatura y genera flujos de ingresos a partir de productos como petróleo, negro de carbón y acero.

¿Qué avances tecnológicos se han realizado en las operaciones de pirólisis?

Los avances tecnológicos incluyen soluciones automatizadas de clasificación y preprocesamiento, junto con sistemas de control de emisiones, mejorando significativamente la eficiencia y sostenibilidad.